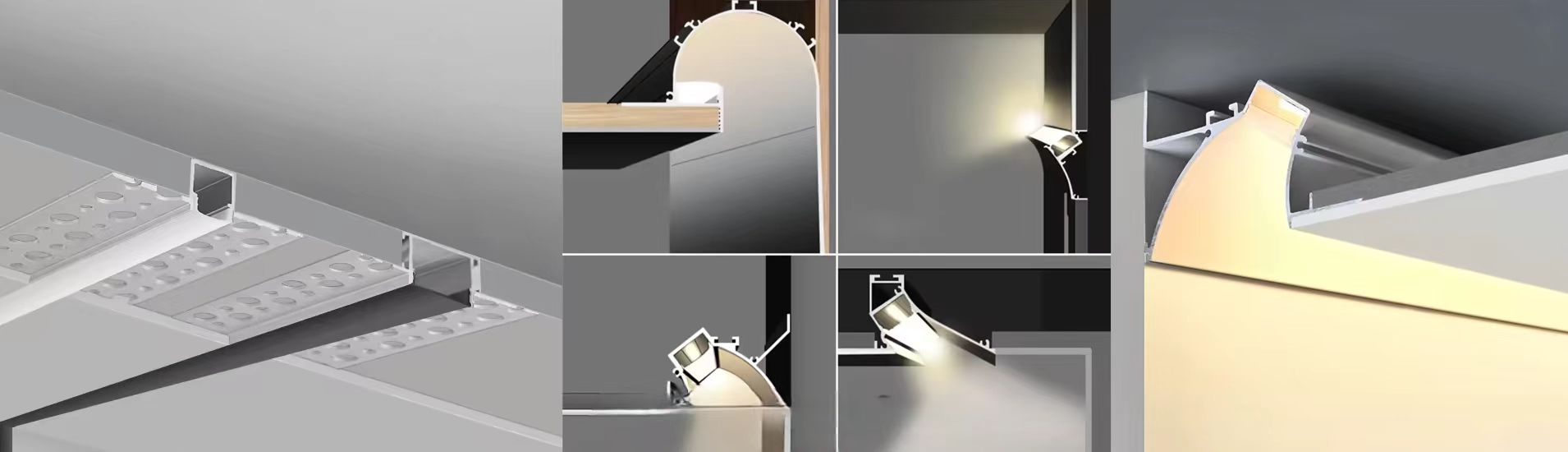

Our Advantages in Manufacturing Strip Light Covers

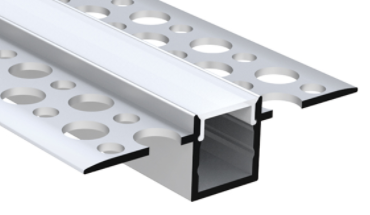

- Quality Control: Clean strip light cover production lines, well management of the plastic extrusion machines .

- Independent Mold Tooling Room: Complete a new LED light plastic cover model within 3 days.

- Skilled Engineers: Able to make new molds, modifications, even advises when comes to complex LED tape extrusions.

- Price: Affordable

- Material: Quality polycarbonate light diffuser made by brand Markolon.

We have developed 25 extrusion production lines, have been in strip light cover for more than 15 years. We export our LED strip light plastic cover to all over the world for those lighting companies. We look forward to the opportunity to cooperate with you and become your reliable supplier.

More Details About Strip Light Cover

LEMON Strip Light Cover Advantages

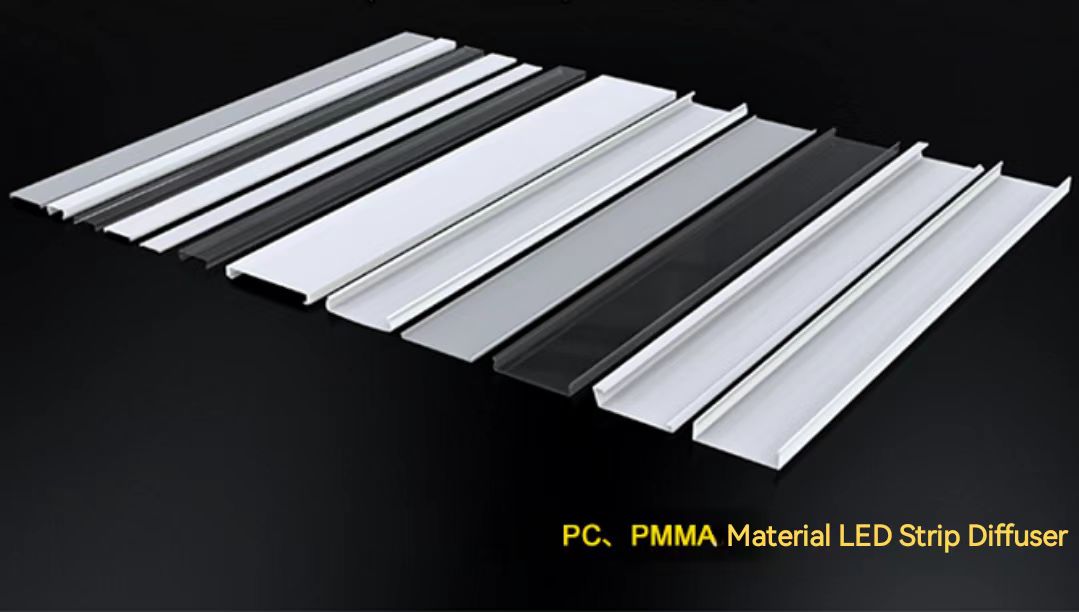

– Light Transmittance: PMMA is above 92%, PC is between 88% and 92%.

– Light Diffusion: PC strip light cover has good light scattering performance, PMMA more concentrated.

– Impact Resistance: PC LED plastic diffuser is not easy to break under large external forces. PMMA is prone to fragmentation under strong impact.

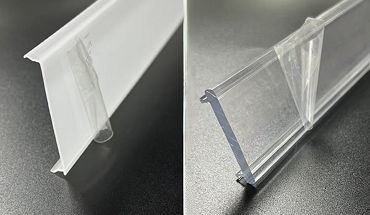

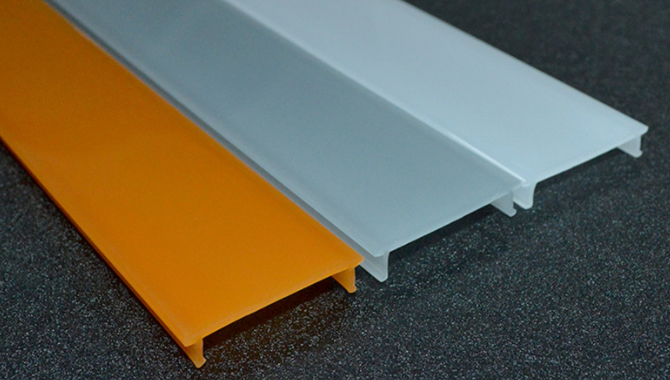

We can custom LED diffuser like colors, mold tooling and surface treatments etc. And we also can make flexible LED light diffuser for such as linear surface mounted light, flush mount linear lighting, and embedded lighting.

We use pure new polycarbonate without recycled materials. LEMON’s PC LED light diffuser has strong ultraviolet resistance and is not easy to age and discolor due to ultraviolet rays. When exposed to ultraviolet rays for a long time, others may turn yellow and become brittle.

This light diffuser cover length can be custom to 2M, 3M, till 6M. Generally each piece of LED polycarbonate diffuser with film are well packed into cardboard tubes or brown cardboard boxes for safe storage and transportation.